Project Overview

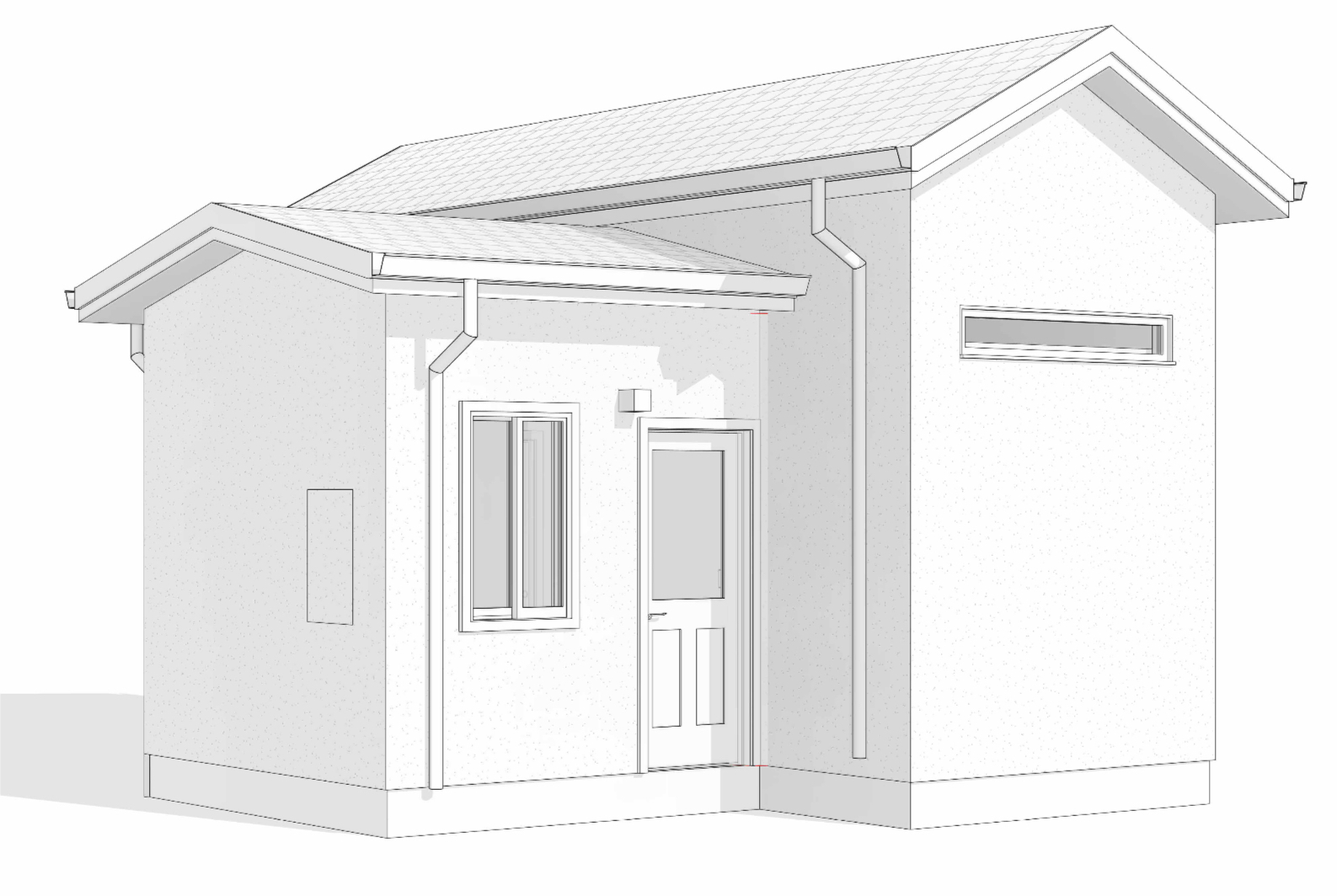

A small infill lot in the Irvington neighborhood is getting a new accessory dwelling unit. The owner chose an off-site–built, steel-framed modular box to speed up delivery and cut waste.

Project Details

A small infill lot in the Irvington neighborhood is getting a new accessory dwelling unit. The owner chose an off-site–built, steel-framed modular box to speed up delivery and cut waste. The module arrives with walls, roof, wiring, and rough plumbing already complete; crews only need to bolt it to a stem-wall slab, hook up the utilities, and finish the cladding. The brief is clear: one bedroom, one bathroom, full kitchen, vaulted ceiling, clerestory windows, and large fold-away doors that spill onto a patio under a pergola.

Design snapshot

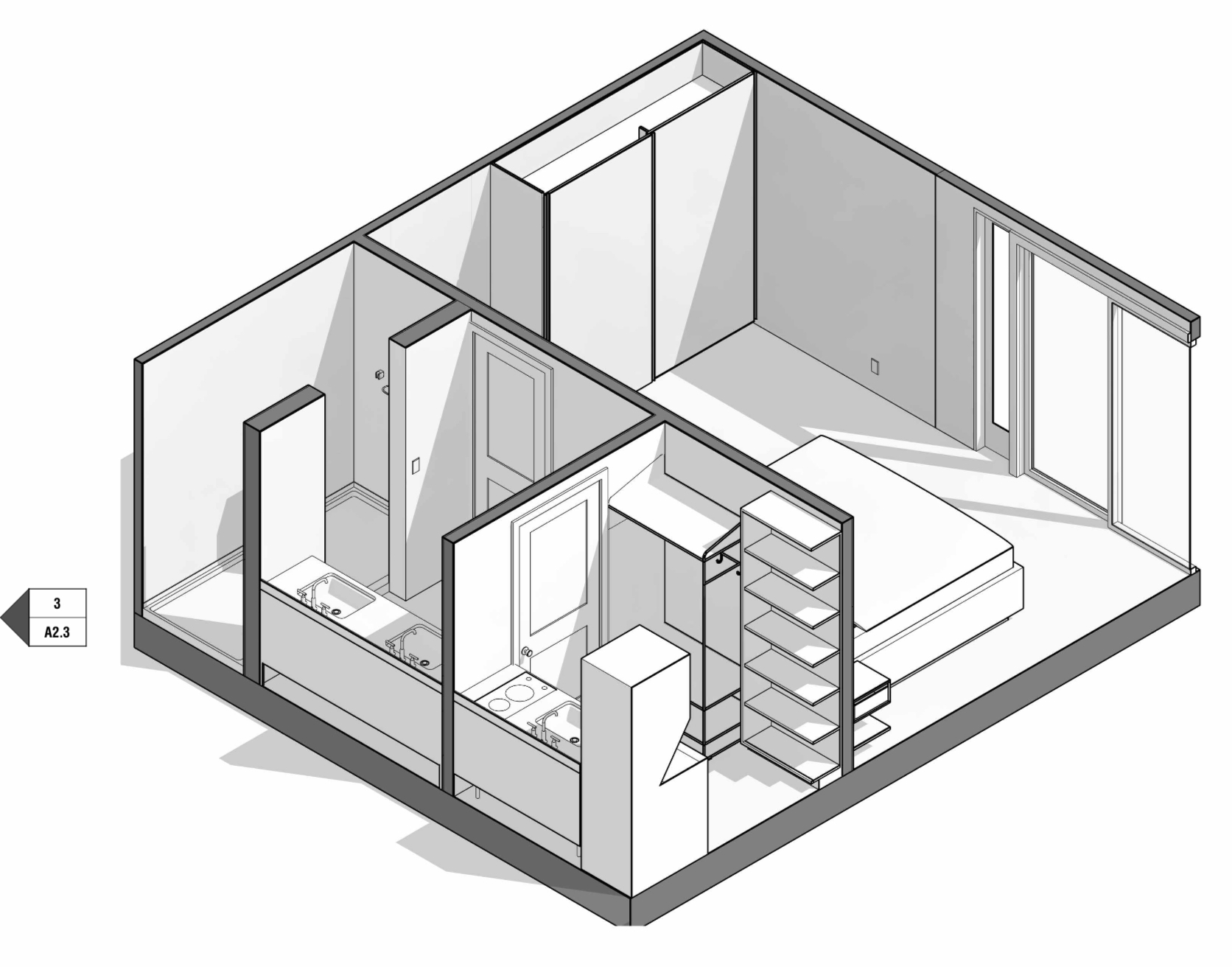

The module is an “L” shape about 450 sq ft inside. A seven-foot-deep covered porch sits in the crook of the L and doubles as weather protection for the entry. Once inside, a single room holds living, dining, and kitchen functions. The kitchen runs the long exterior wall and ships with factory-installed quartz counters, soft-close cabinets, an induction range, and an 18-inch dishwasher. Opposite the cooktop, a six-foot island seats two; when the foldable doors open, that island feels connected to the patio so indoor meals can flow outdoors in seconds.

A pocket door leads to a compact bedroom sized for a queen bed and two built-ins. The adjacent bath uses a five-foot tub/shower combo and wall-hung vanity to save floor space. A stacked washer-dryer hides in its own niche between bath and kitchen. Every interior finish—paint, flooring, trim—goes on in the factory so site time stays short.

Envelope and daylight

A mono-slope roof pitches to the rear, creating a vault that tops out at 11 feet above the living room and slopes to 9 feet at the bedroom. Just below the high roof line, a continuous band of clerestory windows brings daylight deep into the plan while preserving privacy from the side yard. The steel frame accepts 2 × 6 light-gage studs filled with mineral-wool insulation, achieving R-23 walls and an R-38 insulated roof cassette. Exterior cladding is fiber-cement panel with a light sand-float texture; flashings and window trim come in a charcoal powder-coat to resist Fremont’s sea-air corrosion.

Mechanical + water

Cooling and heating rely on a ductless 12-k BTU mini-split mounted high on the living-room wall; the outdoor condenser sits on a pad behind a privacy screen of dwarf bamboo. Domestic hot water comes from a 40-gallon heat-pump electric heater located in the laundry niche. Under-sink canisters deliver three-stage filtration—sediment, carbon, and RO membrane—so both kitchen and bath basins pour purified water without separate countertop units.

Outdoor room

Because Fremont enjoys mild evenings, outdoor living space got equal weight in the program. A site-built pergola with steel posts aligns to the module’s eaves, creating a 10-by-12 patio that feels like an extension of the interior. A simple paver field covers the ground; creeping thyme fills the gaps for a soft, barefoot-ready surface. Low-water shrubs—California fuchsia, dwarf manzanita, and silver carpet—edge the hardscape and keep irrigation demands low. A cedar slat fence frames the courtyard and supports climbing jasmine for seasonal fragrance.

Numbers that matter

- Architect + engineering fees: $12,000 flat, covering modular shop drawings, California-licensed structural review, Title 24, and permit support.

- Construction + finish allowance: $350 per sq ft. That figure includes factory labor, on-site set, crane pick, slab, utilities, interior finishes, appliances, pergola, and landscaping.

- Permit path: Fremont treats detached ADUs under 800 sq ft as ministerial. No public hearing, no design review board, and impact fees are waived for the first 750 sq ft. Submittal scope is architectural set, structural calcs, compliance docs, and PV pre-wire affidavit (solar is required only if total site solar is absent).

Assembly sequence

- Factory build (6 weeks). Module leaves the line with electrical rough-in, plumbing stubs, insulation, drywall, primer, cabinets, and windows installed.

- Site prep (parallel 3 weeks). Local crew pours 18-inch stem-wall slab, trenches 20 feet for sewer tie-in, and runs 1-inch water line from street meter.

- Delivery + set (1 day). A 120-ton crane swings the unit onto the slab, steel plates are welded to embedded straps, and the crew seals the marriage line under the roof plane.

- Hook-ups + finishes (2 weeks). Electric, water, and sewer connections finalize; siding panels, roof membrane, and pergola kit complete the exterior.

- Landscape install (1 week). Drip lines, plants, pavers, and a final blower clean finish the job.

Why steel modular here?

- Speed. Fremont’s rain-lite but permit-heavy climate rewards anything that slashes on-site time. Two months from slab to keys is realistic.

- Strength. Light-gage steel resists termites and won’t twist as it dries—key in a seismic zone that can’t afford soft-story drift.

- Precision. Factory-built walls arrive square, plumb, and dimensionally accurate, easing Title 24 air-leakage targets at inspection.

- Sustainability. Steel framing is 100 % recyclable. The unit’s heat-pump systems and all-electric appliances future-proof it against gas-ban ordinances.

Takeaways for other Bay Area lots

A detached ADU doesn’t need exotic materials or mega budgets to feel special. Start with smart daylighting (clerestories), full-height glazing you can actually open (folding doors), and durable, low-maintenance shells (steel + fiber-cement). Keep systems simple—ductless HVAC, heat-pump water heater, water filtration—so future service calls are rare. Budget clarity matters most: know your all-in cost target—$350 /sq ft in this case—and build every decision around staying inside that envelope.

The Fremont project shows how a modest backyard can host a modern, resilient home without disrupting the neighborhood fabric. One truck-delivered module, a crane pick, two weeks of finish work, and the city gains a new dwelling—ready for parents, renters, or anyone needing a foot in the Bay Area’s housing market.

Our Approach

Discovery & Planning

We analyzed the property, zoning regulations, and homeowner goals to create a customized feasibility plan.

Design

Our designers created custom floor plans maximizing space while respecting the budget and aesthetic preferences.

Permitting

We navigated city requirements and handled all paperwork, securing permits efficiently.

Construction

Our licensed contractors brought the ADU to life with premium materials and meticulous attention to detail.

Understanding Detached ADUs

A standalone accessory dwelling unit built separately from the main home, offering maximum privacy and flexibility. This project in Fremont exemplifies the benefits and possibilities of this ADU type, demonstrating how homeowners can maximize their property's potential while creating valuable living space.

Key Benefits

Ideal For

Fremont ADU Market Insights

Fremont is located in Bay Area and represents one of the most dynamic ADU markets in the area. With a population of 230,000 and median home prices of $1,400,000, the demand for accessory dwelling units continues to grow as homeowners seek to maximize their property value and generate additional income.

Why Build an ADU in Fremont?

ADU Investment Potential in Fremont

Building an ADU in Fremont represents a significant investment opportunity. Based on current market conditions and rental rates in the Bay Area area, homeowners can expect strong returns on their ADU investment. The combination of high rental demand, favorable regulations, and property value appreciation makes this an attractive option for long-term wealth building.

Investment Note: ADUs in Fremont typically pay for themselves within 8-12 years through rental income alone, while also providing immediate property value appreciation. Many homeowners also benefit from tax advantages and depreciation deductions.

Typical ADU Building Timeline in Fremont

Understanding the ADU construction timeline helps homeowners plan effectively. Here's what to expect when building a detached adu in the Bay Area area.

Feasibility & Design

2-4 WeeksSite analysis, zoning verification, initial design concepts, and cost estimation. We assess your property's ADU potential and create preliminary plans.

Architectural Plans

3-6 WeeksDetailed architectural drawings, structural engineering, Title 24 energy compliance, and complete permit-ready documentation.

Permitting

8-12 weeksPermit application submission, plan check review, and approval process. Fremont offers streamlined ministerial review for qualifying ADU projects.

Construction

6-12 monthsFoundation, framing, MEP rough-in, insulation, drywall, finishes, and final inspections. Our licensed contractors manage every phase with quality craftsmanship.

Final Inspection & Move-In

1-2 WeeksCertificate of occupancy, utility connections, final walkthrough, and handover. Your ADU is now ready for occupancy or rental.

Ready to Start Your ADU Project in Fremont?

Get expert guidance on designing and building your own accessory dwelling unit. Our team specializes in Bay Area ADU projects.

ADU Regulations in Fremont

Understanding local ADU regulations is crucial for a successful project. Fremont follows California state ADU laws while implementing local standards. Here are the key regulations that applied to this project and similar builds in the area.

Size Limits

- Detached ADU: Up to 1,200 sq ft

- Attached ADU: 50% of primary home

- JADU: Up to 500 sq ft

- No minimum size requirement

Setbacks

- Rear setback: 4 feet minimum

- Side setback: 4 feet minimum

- No front setback for JADUs

- Conversions: Existing setbacks apply

Height Limits

- Detached: 16-18 feet typical

- 2-story ADUs: Up to 25 feet

- Must not exceed primary dwelling

- Local variations may apply

Parking

- No parking within 1/2 mile of transit

- Garage conversions: No replacement

- JADUs: No parking required

- Tandem parking allowed

Pro Tip: California's ADU laws are updated regularly. Our team stays current on all local and state regulations in Fremont to ensure your project meets current requirements and takes advantage of all available streamlining provisions.

Frequently Asked Questions About ADUs in Fremont

How much does it cost to build an ADU in Fremont?

ADU costs in Fremont typically range from $80,000 for garage conversions to $350,000+ for larger detached units. Factors affecting cost include size, finishes, site conditions, and utility connections. Based on current market rates, a typical detached adu like this project costs approximately $150,000-$350,000.

How long does it take to get ADU permits in Fremont?

Fremont currently processes ADU permits in approximately 8-12 weeks. California law requires cities to approve or deny ADU applications within 60 days. Many jurisdictions, including Fremont, offer expedited processing for standard designs and pre-approved plans.

What is the rental income potential for an ADU in Fremont?

Based on current market rates in Bay Area, a 1-bedroom ADU can rent for approximately $2,600/month, while 2-bedroom units command around $3,200/month. This translates to an estimated annual return of 3.8% on your investment.

Do I need to live on the property to build an ADU in Fremont?

California law prohibits cities from requiring owner-occupancy for ADU permits. You can build an ADU on your property regardless of whether you live there. However, some financing options may have occupancy requirements, and short-term rental rules vary by location.

Can I Airbnb my ADU in Fremont?

Short-term rental regulations vary by city and neighborhood. Fremont has specific rules governing vacation rentals that may require registration, permits, or occupancy requirements. We recommend consulting local regulations and our team can help you understand the options for your specific property.

ADU Services in Nearby Bay Area Areas

GatherADU provides comprehensive ADU design and construction services throughout Bay Area. We serve homeowners in Fremont and surrounding communities with the same expert guidance and quality craftsmanship demonstrated in this project.

Whether you're considering a detached adu like this project or exploring other ADU options, our team understands the unique characteristics and regulations of each neighborhood in the Bay Area area. Contact us to discuss your specific property and goals.

Helpful ADU Resources

Explore our comprehensive ADU resources to learn more about the process, costs, regulations, and design options available to you.

Ready to Build Your Dream ADU?

Let's discuss how we can help you create additional living space, generate rental income, or provide housing for loved ones.