Project Overview

A dusty garage became a stylish apartment, over $24,000 in yearly income, and more than $200,000 in fresh equity—all within eight months and for roughly the price of a new pickup truck.

Project Details

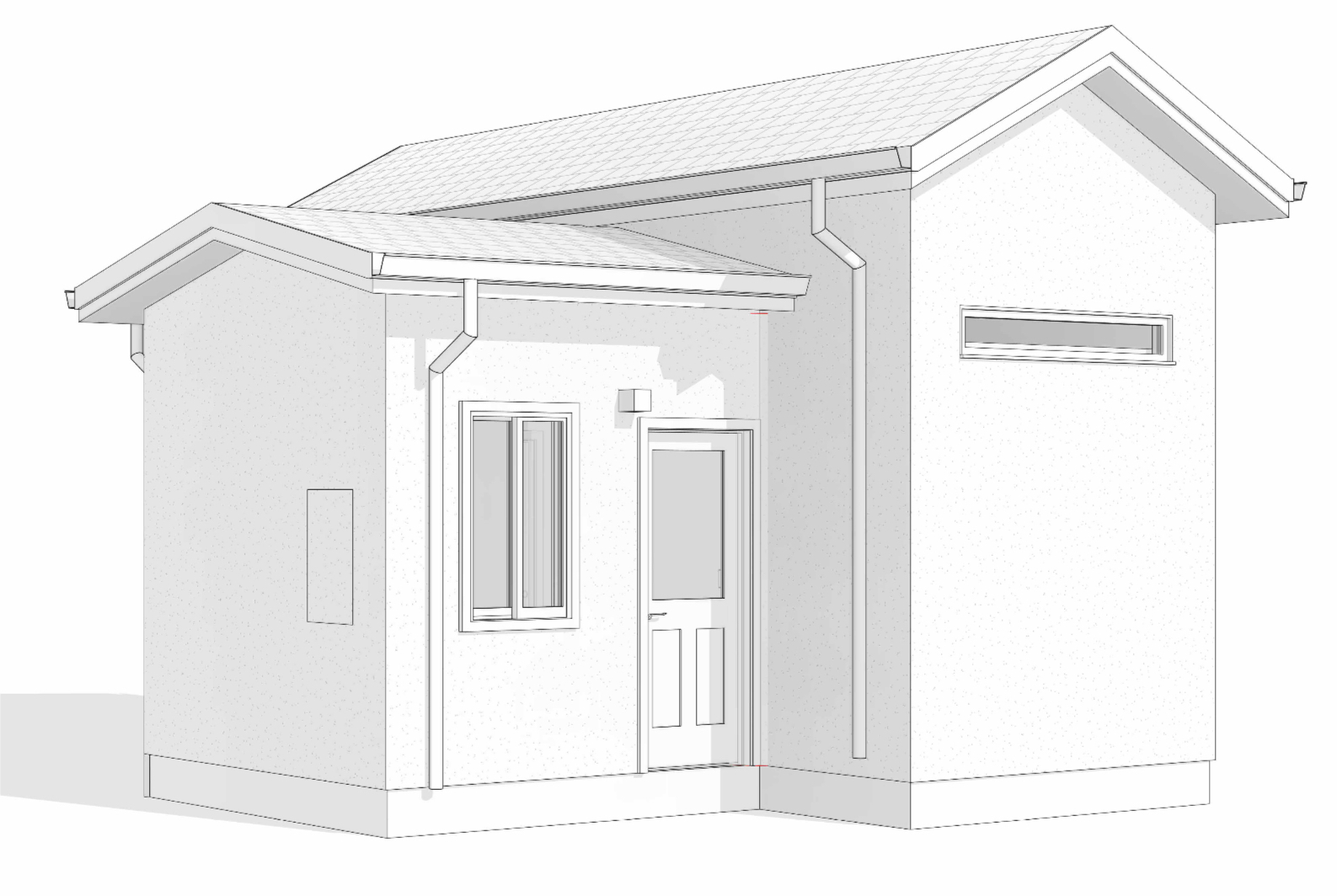

When a rental property investor bought their 1960s ranch house on a quiet Granada Hills street, their detached two-car garage felt more like a dumping ground than a real asset. Cardboard boxes, old bicycles, and half-empty paint cans filled the twenty-by-twenty-foot shell, while the couple wrestled with a sizable mortgage and Los Angeles’ relentless cost of living. Renting out a bedroom inside the main house was a non-starter—privacy mattered—and yet they needed extra income and a plan for aging parents who might one day need ground-level accommodation. Converting that neglected garage into an accessory dwelling unit promised everything at once: steady cash flow now, flexible family space later, and a hefty bump in property value.

.webp)

Seeing the Possibilities

At first glance the structure hardly looked promising. The slab carried hairline cracks, the ceiling topped out at barely eight feet, and a rattling roll-up door hinted at decades of deferred maintenance. Power reached the garage through an overloaded 100-amp service, and no plumbing existed at all. Still, zoning worked in the owners’ favor. The parcel was R1-1, and California’s statewide ADU rules meant a by-right conversion with no discretionary hearings—so long as the design sailed through Los Angeles Department of Building and Safety plan check and cleared the 2022 Title 24 energy standards.

GatherADU’s feasibility walk-through turned skepticism into strategy. Nearby one-bedroom rentals consistently achieved two-thousand-plus dollars per month, so a 400-square-foot ADU would pencil if the couple could hold construction below one-hundred-fifty thousand dollars. They set that figure as an upper limit, listed a full kitchen, in-unit laundry, and respectable finishes as must-haves, and committed to an “amenity level that beats Craigslist but stops short of luxury.” Break-even calculations showed their investment would pay off in under six years at $150 K—and even faster if they could spend less. With goals fixed and budget discipline in place, design kicked off.

Designing Every Inch

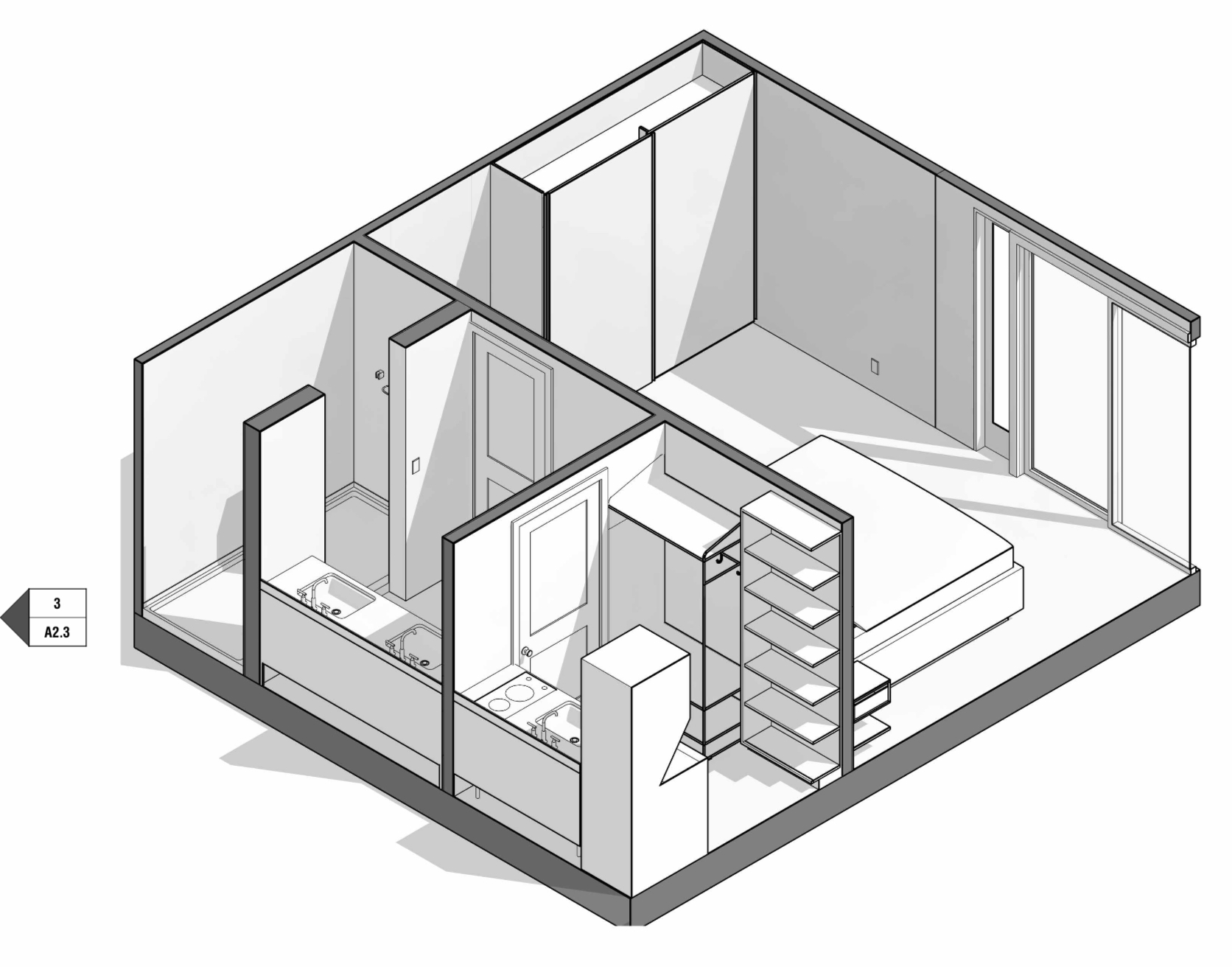

Because every square foot mattered, the design team traced tape lines on the slab and tested half a dozen layouts before settling on the simplest possible arrangement. Along the left-hand wall, a ten-foot kitchen run with 24-inch appliances and a full-height pantry promised genuine cooking capability without crowding. Opposite the kitchen, an eight-foot sliding glass door faced the back yard, drawing daylight deep into the living space and stretching sight-lines well beyond the four hundred feet of interior. A nine-by-ten-foot living zone sat between kitchen and slider; a compact sofa, wall-mounted television, and two-seat dining table fit comfortably. Behind a pocket door, an eight-by-ten-foot bedroom allowed a queen bed with two-foot clearances on both sides, while the back corner held a bathroom and stacked washer-dryer closet. To claw back hidden storage, the designers added an attic hatch and pull-down ladder over the hall, freeing the floor of seasonal clutter.

Finishes followed a strictly modern-but-affordable palette. Seven-inch-wide, white-oak toned luxury vinyl plank slotted wall to wall for durability and waterproofing. Matte-white slab-front cabinets rode soft-close hinges, while long black pulls and matching faucets provided contrast. Arctic-white quartz, cut thick and mitered, formed both countertop and full-height backsplash, a deliberate splurge that felt upscale yet wiped clean in seconds. The bathroom received stacked white subway tile from floor to ceiling, a frameless glass shower panel, and a floating vanity that left the floor plane visually unbroken. Lighting came from half a dozen four-inch LED cans set to a warm 2700-Kelvin temperature. A twelve-thousand-BTU Wi-Fi-enabled mini-split managed heating and cooling, and an eighteen-kilowatt electric tankless water heater tucked neatly into a stud bay, eliminating any need for gas piping.

Solving Structural and Code Hurdles

Charm alone would not earn a permit. Plan checkers flagged shear capacity, slab cracking, and insufficient head height as early red alerts. Engineers specified full-height plywood panels with tension hold-downs at two corners, injected epoxy into the slab’s fissures, applied a liquid vapor barrier, and skimmed the floor with self-leveling underlayment. To capture headroom, carpenters removed the lowest collar ties and re-installed new ones six inches higher—enough to meet code without touching the roof line. All mechanical, electrical, and plumbing lines ran overhead through attic cavities, eliminating costly slab trenching.

.webp)

Permitting in a Digital World

Los Angeles now routes most small-scale residential projects through a fully online portal, a system GatherADU leveraged to the couple’s advantage. A video pre-submittal confirmed the project qualified for over-the-counter review; the first digital upload returned a short correction list focused on shear nailing schedules, Title 24 lighting calculations, and proof that a tandem driveway space satisfied replacement parking rules. Two rapid resubmissions settled every comment, and the coveted “ready-to-issue” stamp appeared in just thirty-nine days. In parallel, Bureau of Sanitation signed off on a four-inch sewer tie-in, and the Department of Water and Power approved a service upgrade from 100 to 200 amps—a crucial move scheduled early to dodge the utility’s notorious backlog.

Ten Weeks on Site

The construction calendar unfolded with almost military precision. Day one demolished drywall and the old garage door; by the end of week one, the slab was patched and ready. Framing crews braced shear walls, set a new laminated-veneer-lumber header over the slider opening, and raised collar ties. Weeks two through three-and-a-half belonged to electricians and plumbers, who pulled a fresh service drop, roughed new circuits, laid PEX water lines, and pushed four-inch ABS to the main sewer. Week four sealed the envelope with R-15 batt insulation in the walls and R-30 blown fiberglass overhead; an on-site blower-door test recorded 3.4 air changes at fifty pascals, comfortably beneath the code maximum. Drywall crews rocked, taped, and achieved a level-four finish in week five, while paint, flooring, cabinetry, and trim occupied weeks six and seven. The mini-split landed mid-week eight, appliances slid into place on week nine, and punch-list cleanup wrapped in week ten. Only two serious risks emerged: LADWP’s three-month service-upgrade queue, which had been pre-empted by filing the request on day one, and a neighbor’s complaint about street parking, which an inspector quashed after confirming tandem driveway compliance.

Budget Breakdown

CategoryCostDesign + engineering + Title 24$ 8,200Permits & city fees3,500Demo & slab repair3,800Framing & structural12,000Electrical (200 A service included)9,000Plumbing & sewer tie-in7,000Mini-split HVAC4,500Insulation & drywall5,300Cabinets & countertops9,000Flooring, paint, trim5,000Fixtures & appliances10,500Exterior patch & misc.7,200Total≈ $110,000

Pinching Pennies Without Paying Later

Landing so far below the original $150 K ceiling required disciplined value engineering. The owners exchanged a custom walnut vanity for a ready-to-assemble model finished in white lacquer, sourced gently used appliances through a builder-surplus warehouse, and accepted stock quartz colors instead of special-order slabs. Together those choices lopped roughly thirty-five thousand dollars from early estimates, yet visitors still describe the finished unit as “nicer than many full-size apartments.”

Living With the Upgrade

Beyond spreadsheets, daily life improved immediately. The rent covers roughly sixty percent of the main-house mortgage, shrinking financial stress and boosting monthly savings. Because the lease runs just one year, the unit can pivot later to house parents, earn higher mid-term rents on platforms like Furnished Finder, or serve as a private office should one owner go fully remote. Maintenance demands remain low thanks to vinyl plank flooring, quartz counters, and soft-close hardware that resists tenant abuse. An all-electric design pairs perfectly with a future six-kilowatt rooftop solar array the couple already plans, pushing utility costs down while shrinking the property’s carbon footprint.

Lessons for Other Homeowners

Several takeaways stand out. Clear objectives set at the very beginning prevented scope creep and cost overruns. Early slab moisture and level testing saved thousands by exposing issues before design locked in. Utility-service applications should go in the same week as plan submittals, because Los Angeles queue times can stall projects for months. Simplicity in layout—one-wall kitchen, pocket doors, minimal interior partitions—both lowers costs and makes a tiny unit feel large. Finally, finishes tenants can see and touch drive premium rents; buyers notice the heft of a solid lever handle and the silence of a soft-close drawer far more than hidden brand names.

.webp)

GatherADU’s One-Stop Approach

From feasibility to lease-up, GatherADU orchestrated every step. The firm delivered cost and rent comps within forty-eight hours, produced complete drawings in four weeks, uploaded and answered plan-check corrections, supervised trades with daily photo logs, and handed the owners a turnkey leasing kit complete with professional photography and tenant-screening templates. The couple never stood in a permit line, never called the power company, and never chased a subcontractor for debris.

A dusty garage became a stylish apartment, $24,000 in yearly income, and more than $200,000 in fresh equity—all within eight months and for roughly the price of a new pickup truck. In a city starving for housing, thousands of similar garages sit ready for the same transformation. If you own one, the next success story could be yours. Schedule a complimentary thirty-minute consultation at gatheradu.com/consult or call (323) 591-3717 and find out how your under-used space can start paying the mortgage, too.

Our Approach

Discovery & Planning

We analyzed the property, zoning regulations, and homeowner goals to create a customized feasibility plan.

Design

Our designers created custom floor plans maximizing space while respecting the budget and aesthetic preferences.

Permitting

We navigated city requirements and handled all paperwork, securing permits efficiently.

Construction

Our licensed contractors brought the ADU to life with premium materials and meticulous attention to detail.

Understanding Garage Conversion ADUs

Converting an existing garage into a fully-functional living space, often the most cost-effective ADU option. This project in Granada Hills exemplifies the benefits and possibilities of this ADU type, demonstrating how homeowners can maximize their property's potential while creating valuable living space.

Key Benefits

Ideal For

Granada Hills ADU Market Insights

Granada Hills is located in San Fernando Valley and represents one of the most dynamic ADU markets in the area. With a population of 58,000 and median home prices of $875,000, the demand for accessory dwelling units continues to grow as homeowners seek to maximize their property value and generate additional income.

Why Build an ADU in Granada Hills?

ADU Investment Potential in Granada Hills

Building an ADU in Granada Hills represents a significant investment opportunity. Based on current market conditions and rental rates in the San Fernando Valley area, homeowners can expect strong returns on their ADU investment. The combination of high rental demand, favorable regulations, and property value appreciation makes this an attractive option for long-term wealth building.

Investment Note: ADUs in Granada Hills typically pay for themselves within 8-12 years through rental income alone, while also providing immediate property value appreciation. Many homeowners also benefit from tax advantages and depreciation deductions.

Typical ADU Building Timeline in Granada Hills

Understanding the ADU construction timeline helps homeowners plan effectively. Here's what to expect when building a garage conversion adu in the San Fernando Valley area.

Feasibility & Design

2-4 WeeksSite analysis, zoning verification, initial design concepts, and cost estimation. We assess your property's ADU potential and create preliminary plans.

Architectural Plans

3-6 WeeksDetailed architectural drawings, structural engineering, Title 24 energy compliance, and complete permit-ready documentation.

Permitting

6-12 weeksPermit application submission, plan check review, and approval process. Granada Hills offers streamlined ministerial review for qualifying ADU projects.

Construction

3-6 monthsFoundation, framing, MEP rough-in, insulation, drywall, finishes, and final inspections. Our licensed contractors manage every phase with quality craftsmanship.

Final Inspection & Move-In

1-2 WeeksCertificate of occupancy, utility connections, final walkthrough, and handover. Your ADU is now ready for occupancy or rental.

Ready to Start Your ADU Project in Granada Hills?

Get expert guidance on designing and building your own accessory dwelling unit. Our team specializes in San Fernando Valley ADU projects.

ADU Regulations in Granada Hills

Understanding local ADU regulations is crucial for a successful project. Granada Hills follows California state ADU laws while implementing local standards. Here are the key regulations that applied to this project and similar builds in the area.

Size Limits

- Detached ADU: Up to 1,200 sq ft

- Attached ADU: 50% of primary home

- JADU: Up to 500 sq ft

- No minimum size requirement

Setbacks

- Rear setback: 4 feet minimum

- Side setback: 4 feet minimum

- No front setback for JADUs

- Conversions: Existing setbacks apply

Height Limits

- Detached: 16-18 feet typical

- 2-story ADUs: Up to 25 feet

- Must not exceed primary dwelling

- Local variations may apply

Parking

- No parking within 1/2 mile of transit

- Garage conversions: No replacement

- JADUs: No parking required

- Tandem parking allowed

Pro Tip: California's ADU laws are updated regularly. Our team stays current on all local and state regulations in Granada Hills to ensure your project meets current requirements and takes advantage of all available streamlining provisions.

Frequently Asked Questions About ADUs in Granada Hills

How much does it cost to build an ADU in Granada Hills?

ADU costs in Granada Hills typically range from $80,000 for garage conversions to $350,000+ for larger detached units. Factors affecting cost include size, finishes, site conditions, and utility connections. Based on current market rates, a typical garage conversion adu like this project costs approximately $80,000-$180,000.

How long does it take to get ADU permits in Granada Hills?

Granada Hills currently processes ADU permits in approximately 6-12 weeks. California law requires cities to approve or deny ADU applications within 60 days. Many jurisdictions, including Granada Hills, offer expedited processing for standard designs and pre-approved plans.

What is the rental income potential for an ADU in Granada Hills?

Based on current market rates in San Fernando Valley, a 1-bedroom ADU can rent for approximately $2,100/month, while 2-bedroom units command around $2,700/month. This translates to an estimated annual return of 4.5% on your investment.

Do I need to live on the property to build an ADU in Granada Hills?

California law prohibits cities from requiring owner-occupancy for ADU permits. You can build an ADU on your property regardless of whether you live there. However, some financing options may have occupancy requirements, and short-term rental rules vary by location.

Can I Airbnb my ADU in Granada Hills?

Short-term rental regulations vary by city and neighborhood. Granada Hills has specific rules governing vacation rentals that may require registration, permits, or occupancy requirements. We recommend consulting local regulations and our team can help you understand the options for your specific property.

ADU Services in Nearby San Fernando Valley Areas

GatherADU provides comprehensive ADU design and construction services throughout San Fernando Valley. We serve homeowners in Granada Hills and surrounding communities with the same expert guidance and quality craftsmanship demonstrated in this project.

Whether you're considering a garage conversion adu like this project or exploring other ADU options, our team understands the unique characteristics and regulations of each neighborhood in the San Fernando Valley area. Contact us to discuss your specific property and goals.

Helpful ADU Resources

Explore our comprehensive ADU resources to learn more about the process, costs, regulations, and design options available to you.

Ready to Build Your Dream ADU?

Let's discuss how we can help you create additional living space, generate rental income, or provide housing for loved ones.

.webp)